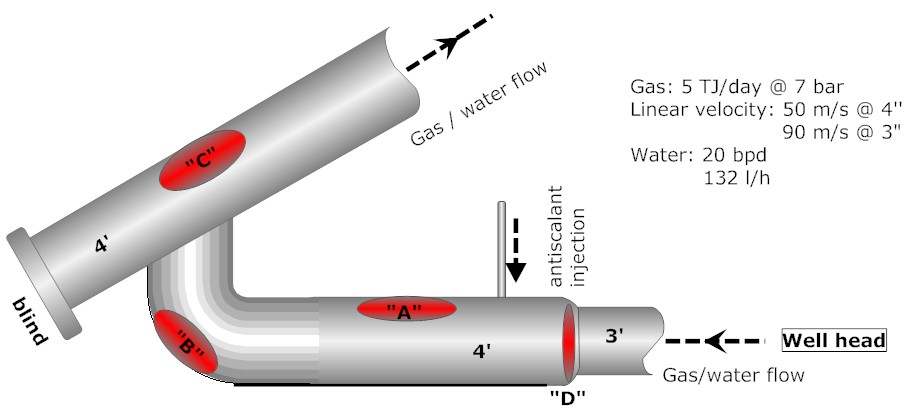

In practice, the corrosion could be the consequence of multiple factors and corrosion mechanisms. Here is the corrosion case in the well head of natural gas wells. The corrosion was identified due to gas water leakage at area B. The further repair found that “A”, “B”, “C” and “D” are severely damaged. The worst metal loss area is “B” , which may experience up to 1 mm/yr. Further failure mechanism analysis confirmed:

1) Flow assisted corrosion caused by high flow rate, the primary deterioration mechanism is chemical injection, which is termed as mixing point corrosion in downstream refinery

2) Corrosvitiy of chemical solution did not diluted further due to small rate of produced water

3) The corrosivity of chemical solution in chemical treatment itself aggravated by dissolved oxygen, which may cause pitting corrosion

4) Welding areas were preferentially attacked (PWC) , potentially by galvanic effect between weldment, HAZ and base metals.

5) “A” seems a synergetic effect of injection quill vortex and chemical corrosivity

6) Area “D ” was attacked due to flow disturbance and galvanic effect of welding

Hi there, of course this article is really fastidious and I

have learned lot of things from it about blogging.

thanks.