Energy Institute (EI) “Guideline on sand erosion and erosion-corrosion management” provides a comprehensive summary on erosion and erosion-corrosion management practice in oil and gas industry.

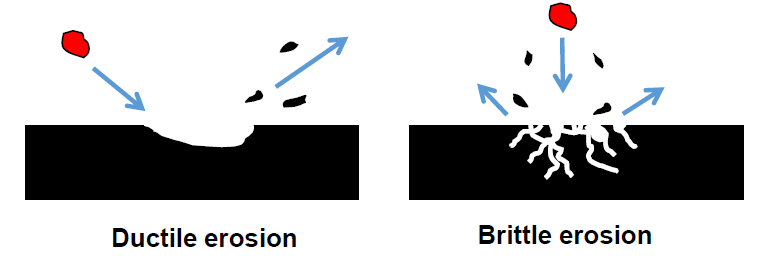

In this guideline, erosion has been defined as e a particle impact on a surface, removing a small amount of material. For ductile material, micro-machining is the major mechanism, while for brittle materials flake of material by micro-crack joining is the mechanism.

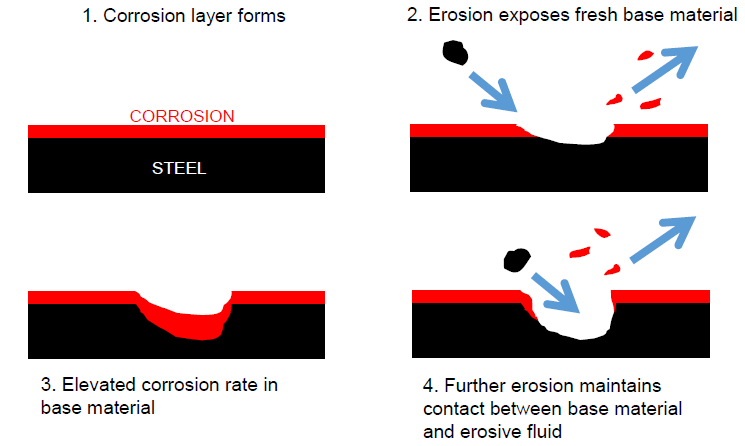

Erosion-corrosion is defined as an interaction between corrosion and erosion. The particle removes the protective layer rather than parent material itself, by this, the corrosion process is accelerated. Only carbon steel, low alloy steel and 13 Cr is susceptible to corrosion- erosion.

Erosion susceptible locations and equipment

- Downhole sand control devices (e.g. sand screen)

- Downhole flow restriction devices (such as subsurface safety valves, emergency shutdown valves, inflow control devices, sliding sleeves, etc)

- Christmas tree and flow line

- Choke valves

- Piping of downstream of choke valves

- Piping bends

- Flow restriction (e.g. some types of flow meter)

- Sand separation cyclone

- Gas export line with solids carryover

- Flare system

- Water reinjection system with solid carryover

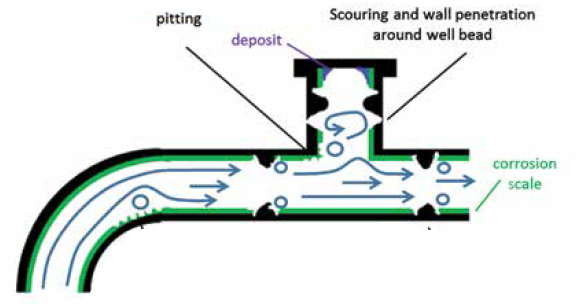

- Flow disturbance location (e.g. weld bead, Tee, etc)

Species causing erosion

- Produced sand ( primary source)

- Fines ( less than 50 um), only in large quantities

- Proppant-primarily during well clean up ( crushed or uncrushed for early well failure due to flow back)

- Drilling cuttings (less likely in high viscosity mud)

- Corrosion and metal particles ( in pipeline, black powder)

- Scale -rarely

- Shale -rareley

Particle size effect

- Fines : less than 50 micron

- Sand: 50~ 2000 micron

- Pebbles: greater than 2000 micron

For particle size less than 100 micron, the metal loss rate is reduced with particle size, therefore, with less damaging than sand. if particle is greater than 100 micron, the metal loss rate is irrelevant to particle size.

Shape

Erosion is proportional to sharpness factor, defined as 1, 0.53 or 0.2 for sharp , semi-round and round particles. Produced sand is classified as semi-round or sharp. The guideline points out a number of production phase while erosion is particularly of the interest:

- In oil system, erosion is often at the start of well life;

- In gas system, the flow velocity at downstream of choke;

- Well at end of life with low pressure and high flow rate;

- Add of tie-in

- Increase flow rate in bottle neck of water production/reinjection;

- Blow down events and process upsets.

Concept of tolerable damage

The guideline brings forward a concept of “tolerable damage”, it includes:

- Piping erosion rate of 0.1 mm/yr without corrosion-erosion

- Factors of inspectability

- Less than 1mm of clad or 30% original clad thickness remains

- Establish criteria for flange joints

- Establish criteria for cage choke valve

- Establish criteria for valves

- Establish criteria for flowmeter

Erosion prediction methodologies

The guideline reviewed different erosion prediction methodologies and indicated:

- API 14E is not recommended for erosion assessment purposes;

- Salama equation, DNV RPO501, SPPS (Tulsa model) and Sandman software is effective as a first pass estimate in simple pipe geometry

- Computational fluid dynamics (CFD) simulation is more appropriate for complicated geometry and close to acceptable limits

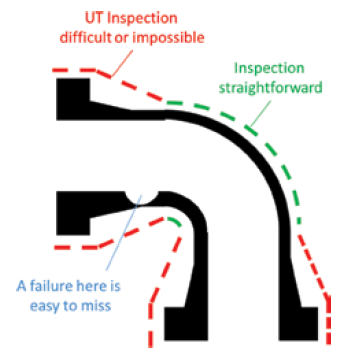

Inspectability

The guideline pointed out some common missing points while planning the inspection.

Monitoring Practices

The guideline reviewed the common sand monitoring practices including acoustic detector, ER probes, choke and sampling.

- Acoustic detector

Accuracy factors: flow velocity, particle size and extraneous noise

- ER probes

location sensitive for monitoring; proper type selection required

- Choke monitoring

Choke performance of flow coefficient (Cv)is utilised as an indicator of flow capacity at a given opening position. The relationship between Cv and internal damage can be established with field experience and CFD flow analysis.

- Sampling

Limitation could be the eruptive nature of sand production, more dedicated sand trap system may be required for this.

Reference

Energy Institute, Guidelines on sand erosion and erosion-corrosion management, 2017

Sand Management on ETAP: A multi-discipline approach, 2014