The atmospheric corrosion is probably the most common forms corrosion in daily life. The corrosion rate of steel is very much influenced by atmospheric environment. Under heavily polluted atmospheric environment, the corrosion is much severer than it in unpolluted environment.

The factors of significance in atmospheric corrosion are time of wetness, rain, fog, dew are all contributing to the wetness. Temperature, particulate matters, wind direction, salt deposition and presence of pollutants etc are of great importance in atmospheric corrosion process. In an urban area and heavily industrial polluted zone, it has been proven both gaseous and solid forms of pollutants are big contributors to the atmospheric corrosion. These include but not limit to H2O2, SOx, NOx, reduced sulphur compounds (H2S, COS, mercaptan etc.), NH3, carboxylic acid, chloride and chlorine containing compounds.

Proper materials selection and design are the only effective way to mitigate atmospheric corrosion, which is unfortunately often neglected in both design and construction. Awareness and knowledge of corrosion mechanisms and corrosion mitigation are of great importance for materials and civil engineers.

Here are some typical examples.

- Example 1-Improper materials selection

This is a design mistake due to underestimation of corrosive environment. This fence is along the river bank near river mouth, where the chloride is deposited by high tide. The foot of barrette were somehow inundated with salty water.

Corrosion damaged fence along river bank

- Example 2-Poor quality control

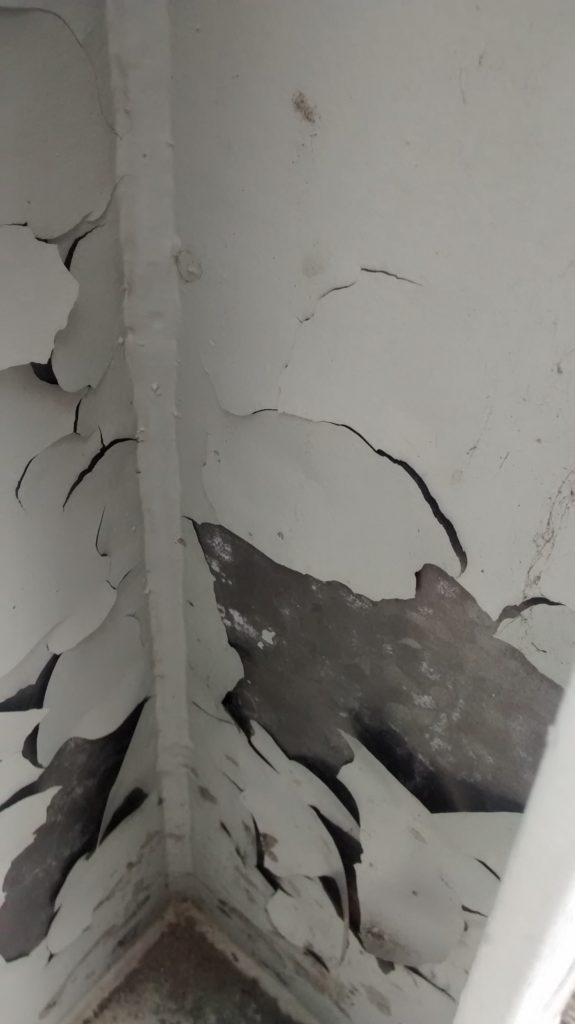

It appears that quality control of coating application is questionable.

Damaged coating in newly furbished utility

- Example 3-Bad construction practice

The bared steel post was buried directly in to the corrosion red soil, which is a perfect environment for soil corrosion.

Soil corrosion due to the direct burial of steel post

- Example 4-Short of awareness on galvanic corrosion and crevice corrosion

Using aluminium alloy rivet as a fastener in carbon steel, creates a galvanic cell to accelerate the carbon steel frame. It is also noted that clamp around the steel post created a good crevice to promote crevice corrosion.

Using dissimilar metals components accelerates the localised corrosion

- Example 5-Lack of knowledge to prevent crevice corrosion

Crevice corrosion around fastener