It is impossible to provide a comprehensive water chemistry list for corrosion purpose. Too many constituents in the water depending on the sources, which cannot be fully explored in detail. Therefore the source of water is critical for the review to understand the trace element and suitability for particular application. Many of water constituents are interactively either positively or negatively regarding to the corrosion process

pH

pH is an indicator of hydrogen ions concentration in the water, which is an index of water corrosivity. The lower the pH, the more aggressive the water in corrosion. Low pH may increase corrosion rate and the strength of oxidizing agents; high pH may protect pipes by favoring effective passivation films and decrease corrosion rates; high pH leads to pitting and SCC and faster degradation of biocide in use. Passivating inhibitors are used in low pH sulphric and phosphoric acid. Non-passivating inhibitors or cathodic inhibitors, e.g. guanidine, and pyridines are preferred corrosion inhibitors for hydrochloric acid.

Alkalinity

alkalinity is the quantity of dissolved earth minerals expressed as CaCO3, Ca(HCO3)2 or Ca(OH)2 . It is an indicator of scale tendency . It is also an important factor for assess the risk of corrosion in water cooling system and boiler, since the higher alkalinity suggested lower corrosivity in water chemistry. There are also P alkalinity (phenolphthalein alkalinity) and M alkalinity (methyl orange alkalinity), which is more based on the indicator used in titration analytical method. P alkalinity titrated with acid to pH 8.2. M alkalinity titrates to pH 4.2, therefore, it also is termed as Total Alkalinity. May help form protective carbonate or hydroxyl carbonate films; helps control pH changes by adding buffering. Low to moderate alkalinity reduces corrosion of most materials. High alkalinity promote high suspended solid, which may adversely affect the efficacy of biocide and filming amine.

Corrosion of steel in alkaline solution is controlled by the rate of oxygen diffusion. Steel is easily passivated in diluted alkaline solution. Aluminum, zinc and lead corrode slowly at low alkali concentration. Higher concentration of alkali (pH>9.0) will lead to accelerated corrosion for these metals.

Metal Cations

Monovalent cations have no measurable effects on inhibitors. Most of divalent cations will form protective precipitates with bicarbonate and sulphate. Higher concentration of divalent cations will precipitate some corrosion inhibitors (e.g. phosphate, silicate, sulfonate etc.)

Total Suspended Solids (TSS)

TSS is caused by clay silt and organism, which gives a cloudy appearance. The filtration/gravimetric method is the most accurate way to measure the TSS.Unfortunately, it is also a time consuming method. Turbidity method is normally utilised in the field to give the indication of TSS. However, there is no general correlation between TSS and turbidity. TSS may settle in the bottom of pipe and promote the growth of bacteria. TSS also adversely affects the efficacy of the filming amine corrosion inhibitor

Total Dissolved Solids (TDS)

TDS is a surrogate for ionic strength, which increases conductivity and corrosion rate unless offset by the formation of passivating films. TDS contributes to both scale formation and corrosion in water system

Hardness(Ca and Mg)

Hardness is the total Ca, Mg, Fe and other metals, it is calculated as CaCO3. therefore, it easily mis-concepted with alkalinity. Temporary hardness usually refers to the carbonate, which can be precipitated as carbonate scale in heating. Permanent hardness refers to the portion cannot be removed by heating, which is mostly sulphate. Ca may precipitate as CaCO3 and thus provide protection and reduce corrosion rates. May enhance buffering effect in conjunction with alkalinity and pH.

temporary hardness ≤ p alkalinity

Permanent hardness = total hardness – total alkalinity

Chloride

Chloride is notorious in corrosion protection since it is a strong depassivating agent and cause severe pitting in stainless steel surface. High chloride concentration also increased the risk of stress corrosion cracking in austenitic stainless steel. Field experience showed that corrosion in chloride rich environment tends to be more severe in fouling surface or surface with deposition. The higher the concentration of the chloride, the higher the concentration of passivating inhibitor required.

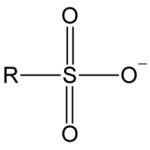

Sulphate

sulphate scale is normally been taken as hard scale. It can not be easily removed by acid or heating. High levels increase corrosion of iron. sulphate are causative agent of the various types of concentration cell corrosion that cause pitting and crevice attack. The sulphate also promotes the depassivation the metals surface and growth of biofilm, which is the cause for the deep pin hole leak. Sulphate may also cause interference with certain aliphatic (long carbon chain) biocide and corrosion inhibitors.

Silica

Silica dissolved in water while water contacts with sand and rock. silica is the cause of very hard and tenacious scale, that can cause severe heat transferring issue. It also prevents chemical to contact with metal surface, therefore reduced the chemical/biocide treatment efficiency. However, silica is an effective corrosion inhibition additives for water distribution systems.

Hydrogen sulphide

Increases corrosion rates; may convert to sulphite and promote growth of bacteria

Ammonia

May increase solubility of some metals, also a nutrient for bacteria, in higher pH range, acting as pH buffer

Polyphosphates

May reduce tuberculation of iron and steel, and provide smooth pipe interior. May enhance uniform iron and steel corrosion at low dosages, Prevents CaCO3formation and deposition. Sequesters ferrous iron and reduced manganese, especially at pH below 7.is a nutrient for bacteria growth

DO

Increases rate of many corrosion reactions when metal is passive or immune under anodic conditions. May help form better passivating oxide films on some materials, such as iron. Organic inhibitors are not generally effective against oxygen caused corrosion unless they contain passivating groups such as benzoates or sulfonates. In some case, extreme high concentration of filming amine maybe used for oxygen corrosion inhibition.

Chlorine residual

Increases metallic corrosion, particularly for steel.

Temperature

Typically concern while water is sourced from industrial process, such as RO or power plant recycling.

Pingback: How does pipe corrosion impact water quality? - TAPP Water