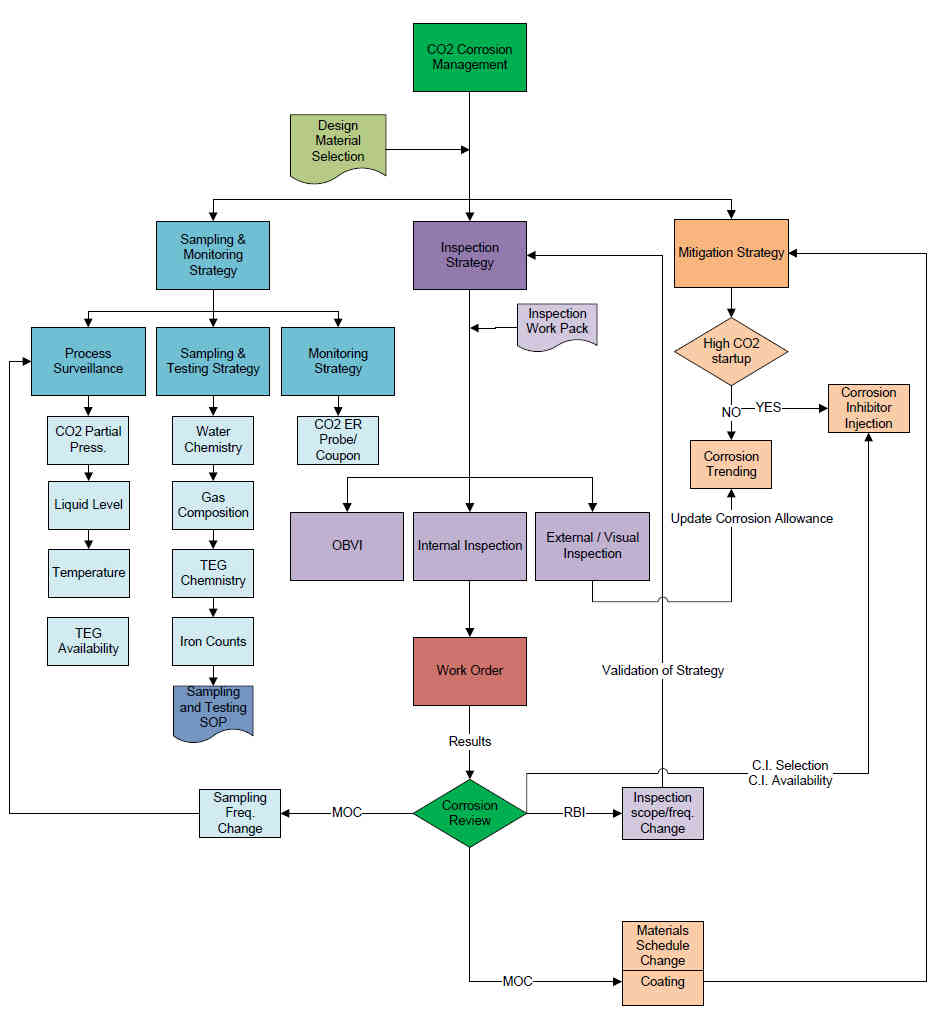

In oil and gas upstream, CO2 corrosion is always a primary concern for widely used, cost efficient mild carbon steel equipment. The reaction mechanism of CO2 with mild carbon steel has been studied for decades by scientists and engineers. Success of CO2 corrosion control practice in oil and gas industry relies on a systematic approach rather than a single technical solution. Multiple technical teams e.g. design, process, operation, asset integrity, production chemistry and corrosion engineering need work together to handle the complex CO2 corrosion.

A good industrial practice suggested that proa

ctive activities in corrosion monitoring, sampling and testing, inspection and mitigation are essential in CO2 corrosion management. Materials selection and coating design are usually the first defence line of CO2 corrosion. During the production stage, on line monitoring, sampling and testing, combining with process surveillance, provide an effective avenue for the reality check against the design base as well as corrosion trending. Corrosion inhibition program is a mitigation option. Typically, inhibitors are effective in sweet systems (CO2) to control general corrosion, but usually are less effective for “mesa corrosion” and pitting corrosion. The availability of corrosion inhibitor is always the challenge in practice for CO2 corrosion control. This is a summary of the best industrial practices in CO2 corrosion control for upstream. “Practices of CO2 Corrosion Control in Oil and Gas Upstream” can be viewed or downloaded here.