Introduction

DC stray current is defined as current flowing through the path other than the intended. The DC stray current could be either natural sources, e.g. telluric, metallic mineral deposit, or artificial sources, e.g. foreign pipeline, HVDC transmission line, DC tram, etc. DC stray current is a big threat in pipeline integrity. The severity of the risk is a related to the soil resistivity: the lower the soil resistivity, the more likely to form such electrical conductance path, i.e. stray current related corrosion. The root cause of sewer explosion in 1992 Guadalajara Mexico is stray current corrosion of ductile iron pipe.

DC Stray Current Detection

Asset owner and corrosion engineer need to be vigilant to the sources of DC stray current including other pipeline cathodic protection units, HVDC transmission lines, DC railway and trams, solar farms, smelting plants, electroextraction plants etc. corrosion engineer should also be aware of latent sources such as telluric effect, strong magnetic deposit. Once suspected source of DC stray current is identified, further detailed monitoring should be planned to identify the magnitude of interference, assess the risk level to pipeline integrity and mitigation requirements.

- Pipe-to-Soil change along the pipeline caused by an interference source

- Change of line current magnitude and direction by an interference source

- Localised corrosion near an interference source

- Localised coating damage in the vicinity of an interference source

DC Stray Current Measurement

Using close interval potential survey (CIPS) to determine stray current pickup and discharge region

The principal anodic areas along the pipeline should be located. Sufficient cathodic protection current should be applied to cause a net protective current from the electrolyte to the pipe surface. The structure-to-electrolyte potential measurements by using close interval potential survey (CIPS) technique are performed on piping that is not cathodically protected. The structure-to-electrolyte potential survey, when used as a tool for locating probable anodic conditions on unprotected pipe, should be conducted by making individual readings at 3 m (10 ft) intervals along the route of the pipe. Probable anodic conditions are indicated at survey points where the most negative readings are determined. It may be desirable to confirm these suspected anodic conditions by making the two-reference-electrode test lateral to the pipe as described for the two reference-electrode method described below.

Direct Current Voltage Gradient method for current flow

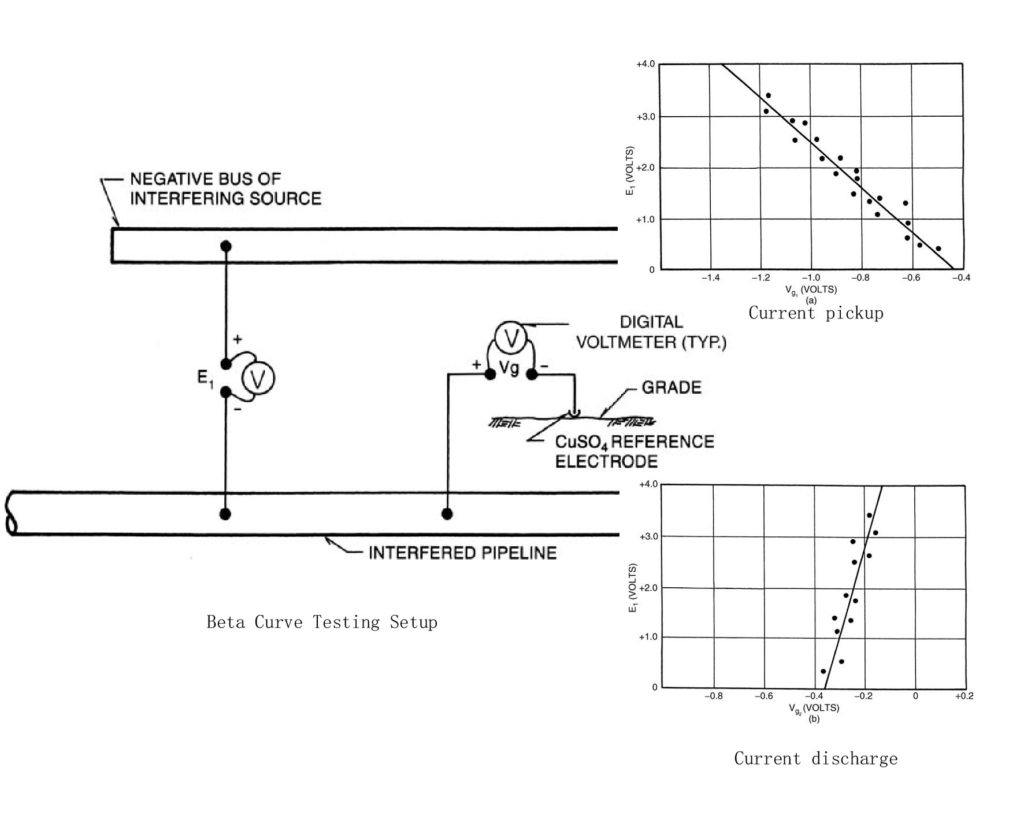

Beta Curve to determine stray current pickup and discharge

The direct current voltage gradient (DCVG) method, i.e., two-reference-electrode potential survey measures the direction of the potential gradient along the earth’s surface. Measurements should be made at 3 m (10 ft) intervals directly over the centerline of the pipe. This method is used to detect the probable current discharge (anodic) areas along a pipeline as well. However, this method is more appropriate to poor coated and/or bare pipeline. For well coated pipeline, the voltage gradient is not used as a standalone method for identifying stray current pick up and discharge. Suspected anodic conditions and their magnitudes can be confirmed by making two-reference-electrode tests laterally to the pipeline. One reference electrode is placed over the line and the other spaced laterally the same distance as for the transverse measurements over the line. These tests should be made on both sides of the pipe to verify that current is leaving the line.

Line Current Direction and Magnitude Measurement

It is important to use line current flowing direction to determine source and extent of stray current pickup and discharge section. This may be performed by Swain Clamp, two wire span method, four wire span method outlined in line current measurement.

DC Interference Mitigation

- Auxiliary CP, either impressed current or sacrificial anode, is utilised to compensate the too positive potential around current discharge region

- An interference cell, normally a bank of sacrificial anodes, is installed as a stray current discharging point;

- Sacrificial anodes are installed on both interfering and interfered structures to allow safe discharging of stray current between two.

- Relocating interfering anodes

- Shielding and/or recoating current pickup section to limit the stray current magnitude;

- Design and install electrical resistance bond to allow the return of stray current safely.

Mitigation Effectiveness

CIPS after the mitigation

CIPS to confirm the pipe-to-soil potential in current discharge section to acceptable level

Line Current Measurement after the mitigation

Line current measurement to confirm no current discharging

Beta curve confirmation for the slope of maximum of exposure section

Develop the beta curve to identify the most severely affected sections. This is most valuable for the dynamic interference sources, e.g. telluric, DC tram and railway etc. If the CP unit is operated under auto potential mode, its anode bed may also be taken as dynamic interfering source.

Wow, that’s a really clever way of thikinng about it!

I’m not certain where you are getting your information, however

great topic. I needs to spend some time studying more or understanding more.

Thanks for magnificent info I used to be searching for this info for my mission.