AC corrosion became a known issue since more and more pipelines are sharing ROW with HVAC transmission lines. It is caused by the metal loss due to AC current leaving the pipeline. There are three different types of AC interference, which are the source of such AC current.

Electrostatic Coupling

This is also called capacitive interference. It may only happen to well insulated (not grounded) structure, e.g. above ground test station, pipeline near ditch or in stock yard

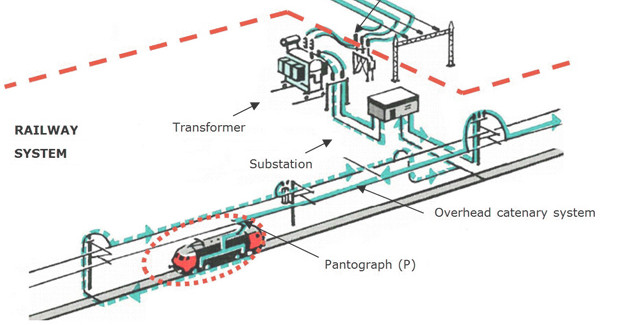

Electromagnetic Coupling

This is also called inductive interference. This is the most often seen AC interference mechanism, in which pipeline is acting as a secondary coil (inductive coil). This may happen for both buried or above ground structure as long as inductive conditions are met. While pipeline and HVAC are sharing ROW, it became most important factor for AC interference and AC corrosion.

Conductive Coupling

This is also called resistive interference, in which a faulty AC current find a path returning to local earth. The structure became part of this faulty current return path. This will only occur in buried in structure. When the AC current leaves the structure, AC corrosion occurs. Conductive coupling does require parallel of structure with HVAC. This typically happen in the proximity of substation

Industrial Practice /Standard for AC corrosion

- NACE SP 0177 Mitigation of Alternating Current and Lightning Effects on Metallic Structures and Corrosion Control Systems

- ANSI / IEEE Standard 80 Guide for Safety in AC Substation Grounding

- EPRI/AGA Mutual Design Considerations for Overhead AC Transmission Lines and Gas Pipelines

- CAN/CSA-C22.3 No.6-M91 (R2009) Principles and Practices of Electrical Coordination Between Pipelines and Electric Supply Lines

- BS EN 15280:2013 Evaluation of A.C. Corrosion Likelihood of Buried Pipelines Applicable to Cathodically Protected Pipelines

AC Corrosion Likelihood Assessment

NACE SP 0177 suggested 15 VAC as criterion. However, it admits this criterion is for personal protection rather than AC corrosion protection. It only states “The members of NACE Task Group (TG) 025 agreed that any criteria for AC corrosion control should not be included in this standard”

European standard EN 15280 may be more specific on the AC corrosion protection criteria. Within the latest version (2013), it suggested the two approaches to assess the AC corrosion risk:

AC Potential

- In the presence of less negative than -1200 mV s. CSE On-Potential, up to 15VAC is allowed

- In the presence of more negative than -1200 mV v.s. CSE On-Potential, lowest possible AC voltage is required.

AC Current Density

AC/DC current density ratio is utilised for AC corrosion likelihood. As long as it below the threshold, no AC corrosion can occur since the metal oxidisation in the anodic half wave is suppressed by DC current

- AC current density (rms) lower than 30 A/m²

- CP current density lower than 1 A/m if a.c. current density (rms) is more than 30 A/m²;

- Maintaining the ratio between AC current density (Ja.c.) and DC current density (Jd.c.) less than 5

Soil Resistivity

The lower the soil resistivity, the higher the AC corrosion risk. For HDD or cased pipeline with bentonite refill, the AC corrosion risk, therefore, is high.

- Below 25 Ωm : very high risk,

- Between 25 and 100Ωm: high risk,

- Between 100 and 300 Ωm: medium risk,

- Above 300 Ωm: low risk.

Corrosion Rate by Corrosion Probe or Coupon

Mitigation Methods

Bedding and backfill materials change

Typically sand and other high soil resistivity type of soil should be used in AC interference susceptible area. Limitation is sand can be eluted, drained or mixed with other low resistivity soil and alleviate the effectiveness of the method.

Increase electrical isolation

This is only useful for inductive coupling by reducing the longitudinal length of conductor (i.e. pipeline). This method is not effective for resistive coupling interference.

Installation of insulated wire

A wire in close proximity of pipeline may modify the interference. It should be considered as short term rather than long term mitigation. In no case, the bared metal wire should be utilised for this purpose, since it may aggravate the AC corrosion in the vicinity of coating defects due to resistivity coupling

Additional earthing methods

Bond zinc ribbon, magnesium anodes, copper directly or through PCR/SSD etc.

AC compensation devices

To compensate by imposing an antiphasing AC to generate artificially zero resistance earth.

Control the CP level

- Maintaining the ratio between AC current density (Ja.c.) and DC current density (Jd.c.) less than 5

- CP current density lower than 1 A/m if a.c. current density (rms) is more than 30 A/m²